Direct-to-film (DTF) transfer printing offers high-quality, vibrant image reproduction on various surfaces. To start a DTF project, gather materials including DTF transfers, printer, ink, and workspace tools. Prepare designs in high resolution with vector outlines for optimal results. Follow a three-step process: design setup, printing to film, and application. After printing, allow cooling, gently peel the film, and promptly clean prints to maintain quality. Meticulous preparation and precise settings are crucial for excellent DTF transfers.

“Unleash your creativity with the direct-to-film (DTF) transfer process and bring your designs to life on various media. This comprehensive guide offers a step-by-step journey through DTF printing, from understanding the technology to achieving high-quality results. We’ll walk you through gathering materials, preparing your design software, applying transfers, and post-print care. Discover tips and tricks to master DTF techniques, ensuring vibrant and precise prints. Elevate your DIY projects with the magic of DTF Transfer.”

- Understanding Direct-to-Film (DTF) Transfer: A Basic Overview

- Gathering Materials and Preparation for Your DTF Print Project

- Choosing the Right Image and Setting Up Your Design Software

- Applying the DTF Transfer: Step-by-Step Instructions

- Post-Print Care and Processing of Your DTF Prints

- Tips and Tricks to Achieve High-Quality DTF Transfers

Understanding Direct-to-Film (DTF) Transfer: A Basic Overview

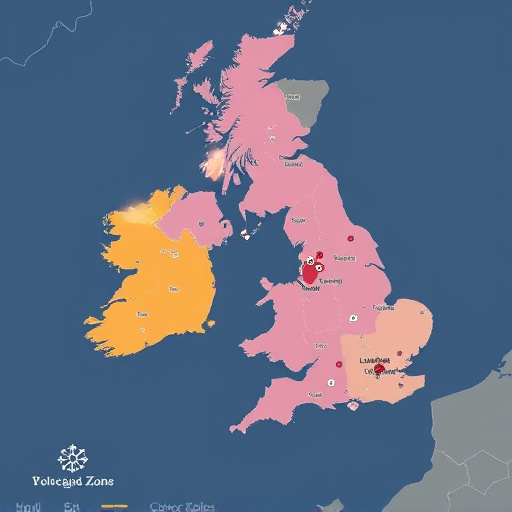

Direct-to-film (DTF) transfer is a printing process that allows for high-quality reproduction of images directly onto various surfaces, such as fabric, metal, or wood. Unlike traditional methods that require separate ink and medium, DTF uses specialized printers and inks designed to bond directly with the substrate, resulting in vibrant colors and lasting durability. This efficient technique has gained popularity among artists, designers, and small businesses due to its ability to produce custom prints swiftly and cost-effectively.

The DTF transfer process involves several key steps: preparing the design or image, selecting the appropriate substrate, choosing the right DTF printing material, and utilizing specialized printers. Once the design is finalized, it’s digitally printed onto a transparent film using UV-curable inks. This film acts as a mask, allowing precise control over where ink is transferred to the substrate. The printed film is then carefully applied to the desired surface, followed by curing with UV light to ensure the ink permanently bonds. This innovative approach offers unparalleled versatility, enabling users to transform their creative visions into tangible products with exceptional detail and color accuracy.

Gathering Materials and Preparation for Your DTF Print Project

Before you begin your direct-to-film (DTF) print project, it’s essential to gather all necessary materials and prepare your workspace accordingly. Start by acquiring high-quality DTF transfers that are compatible with your desired substrate. These transfers, often made from vinyl or other heat-transfer materials, come in various designs and sizes, catering to different projects. Ensure you have a suitable printer capable of handling DTF printing, along with the necessary ink and media.

Next, set up your workspace by clearing a flat, clean surface for your project area. Gather additional tools like a heat press or iron, protective gear, and a timer. Prepare your substrate by cleaning it to ensure optimal adhesion. Whether you’re working on t-shirts, mugs, or other items, proper preparation ensures the best results with DTF printing.

Choosing the Right Image and Setting Up Your Design Software

When creating direct-to-film (DTF) prints, selecting the perfect image is the first step in achieving exceptional results. The right choice should be high-resolution, with vibrant colors and sharp details, as these elements directly influence the final print quality. Consider the intended use of your DTF transfer; whether it’s for clothing, signage, or other materials, ensuring the image aligns with these requirements is essential. For example, a design meant for fabric should have a smooth, vector-based outline to prevent pixelation when scaled up.

Setting up your design software is crucial for successful DTF printing. Familiarize yourself with industry-standard programs like Adobe Illustrator or CorelDRAW, which offer precise control over vector and raster elements. Ensure your software supports DTF printing by having the necessary export settings and plugins. Create or import your desired image, adjust colors, and refine the design to meet your vision. The setup process involves configuring print settings specific to DTF transfers, including resolution, color profiles, and the chosen output medium.

Applying the DTF Transfer: Step-by-Step Instructions

Applying the DTF Transfer: A Simple Guide

To begin the process of using direct-to-film (DTF) prints, you’ll first need to prepare your design. Ensure it’s in a suitable format and resolution for printing. Once ready, follow these steps:

1. Place the DTF transfer sheet onto your printing surface. These sheets are designed to adhere temporarily, allowing precise positioning.

2. Using a printer specifically designed for DTF printing, output your design directly onto the transfer sheet. The heat from the printer will activate the adhesive, ensuring a strong bond with the film.

3. Carefully peel back one edge of the transfer sheet to check the print quality and ensure it’s aligned correctly. Adjust as needed before proceeding.

Post-Print Care and Processing of Your DTF Prints

After completing your direct-to-film (DTF) prints, proper post-print care is essential to ensure the longevity and quality of your DTF transfers. Start by allowing the prints to cool down before handling them; hot DTF films can be delicate and may cause smudging or peeling if not handled carefully. Once cooled, gently peel the film away from the print surface, ensuring you do not stretch or apply excessive pressure, as this can distort the image.

Next, it’s crucial to process your DTF prints promptly to prevent any potential degradation. Remove any residual ink or debris using a clean, soft cloth or brush. You may also want to consider using a mild detergent or cleaning solution specifically designed for DTF printing to ensure thorough cleaning. After cleaning, thoroughly dry the prints with a microfiber towel or let them air dry in a dust-free environment. Proper storage is key; keep your DTF prints in a cool, dry place away from direct sunlight to prevent fading or warping over time.

Tips and Tricks to Achieve High-Quality DTF Transfers

Achieving high-quality direct-to-film (DTF) transfers requires a bit of finesse and some clever tricks. Firstly, ensure your prints are crisp and clear; any pixelation or blur will be amplified when transferred to film. Use high-resolution images and consider upscaling if necessary; this preserves detail during the printing process. Secondly, the surface preparation is key. Clean the film thoroughly before printing to prevent any smudges or contaminants from affecting the final transfer. A slightly damp cloth can help remove dust and oils without damaging the film’s surface.

Another tip involves calibrating your printer settings precisely. Play with exposure times and print density to get the best results; too much or too little ink will impact the final quality. Test prints on scrap material first to find the optimal settings. Additionally, consider using specialized DTF printing papers designed for optimal ink adhesion and transfer. Lastly, be patient during the curing process; allow enough time for the ink to fully set, as rushing this step might lead to smudging or fading.