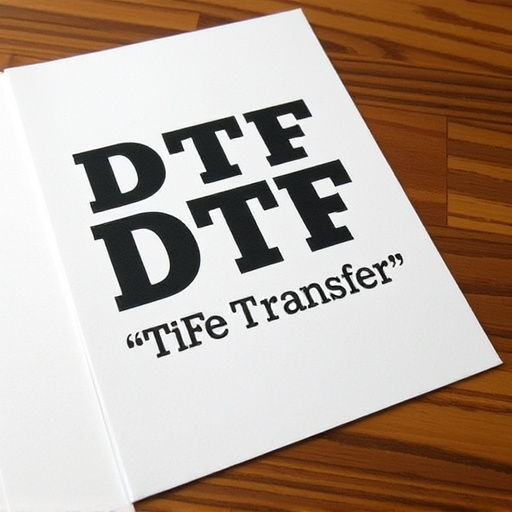

Direct-to-Film (DTF) printing is a cutting-edge method offering high-quality imaging directly onto various film materials, attracting professionals and amateurs for its versatility in creating visually stunning effects. To begin, gather essential tools like a suitable DTF printer, print media, cutting tools, workspace setup, inks, and protective gear. Design preparation includes optimizing resolution, color mode, file format, and ensuring color consistency. Applying DTF ink requires careful dispensing and gentle film placement, followed by drying according to manufacturer guidelines. Heating and curing at 120°C-180°C (248°F-356°F) for specific times sets the ink, enhancing durability. Proper care involves cleaning, storage in cool, dry conditions, and regular inspection to maintain print quality and longevity.

“Unleash your creativity with Direct-to-Film (DTF) printing—a game-changing technique for beginners and experts alike. This comprehensive guide will walk you through each step, from understanding the basics of DTF to mastering the art of print preparation and application.

Learn how to gather the essential tools, prepare your designs, and apply DTF ink with precision. Discover the secret to achieving high-quality, durable prints by heating and curing them correctly. Finally, explore post-print care tips to ensure your DTF creations last. Get ready to dive into the world of DTF!”

- Understanding Direct-to-Film (DTF) Prints: A Beginner's Guide

- Gathering the Necessary Tools and Materials

- Preparing Your Design for Print: Tips and Best Practices

- Applying the DTF Ink: Step-by-Step Process

- Heating and Curing the Print: Ensuring Quality and Durability

- Post-Print Care and Maintenance: Maximizing Your DTF Results

Understanding Direct-to-Film (DTF) Prints: A Beginner's Guide

Direct-to-Film (DTF) printing is a cutting-edge technique that allows for high-quality, long-lasting imaging directly onto various film materials. This method has gained popularity among professionals and hobbyists alike due to its versatility and ability to produce stunning visual effects. For beginners, understanding the basics of DTF prints is essential to unlocking its full potential.

DTF printing involves a direct transfer of digital art or design onto a selected film substrate using specialized equipment. Unlike traditional printing methods, it eliminates the need for intermediate steps like plates or screens. This process offers several advantages, including precise color reproduction, fine detail retention, and the ability to print on unconventional surfaces. Whether you’re looking to create custom stickers, artistic projections, or unique product packaging, DTF prints provide a creative outlet with endless possibilities.

Gathering the Necessary Tools and Materials

Before you embark on your direct-to-film (DTF) printing journey, it’s crucial to gather all the necessary tools and materials. This process requires specific equipment to ensure optimal results. Start by acquiring a high-quality DTF printer, which is the backbone of your operation. Choose one that aligns with your project requirements and budget. Next, source quality print media suitable for DTF printing. This typically includes transparent film or vinyl sheets designed for direct application on various surfaces. Remember to select materials that offer excellent adhesion and durability.

Additionally, you’ll need precision cutting tools like a craft knife or a cutting plotter to meticulously cut your designs from the print media. Having a clean workspace with adequate lighting is essential. Consider investing in printing inks specifically formulated for DTF applications, ensuring vibrant colors and long-lasting results. Basic maintenance supplies such as cleaning solutions and brushes will also come in handy for regular care of your printer. Lastly, gather protective gear like gloves to safeguard yourself during the intricate cutting and application process.

Preparing Your Design for Print: Tips and Best Practices

Preparing Your Design for Direct-to-Film (DTF) Print:

Before sending your design to be printed using DTF technology, it’s crucial to ensure that your file is optimized for optimal results. Start by checking the resolution; aim for a minimum of 300 DPI (dots per inch) to guarantee crisp and clear images. Since DTF printing directly on film, color profiles and mode settings are critical. Using CMYK color mode is standard, ensuring accurate representation during the printing process. Additionally, ensure your design has no visible artifacts or imperfections, as these might be amplified when printed at a large scale.

When preparing your design, consider file format; PNG or EPS are ideal choices for DTF printing. Remove any unnecessary elements or transparency effects that could complicate the print setup. Also, check for color consistency across different parts of your design to maintain visual harmony after printing. These best practices will help you create a design that translates well into a stunning direct-to-film print.

Applying the DTF Ink: Step-by-Step Process

Applying DTF (Direct-to-Film) ink is a precise process that requires careful steps to ensure optimal results. Begin by preparing your work area, donning protective gear like gloves and ensuring good ventilation. Next, carefully dispense the DTF ink onto a clean, flat surface using the provided applicators or pins. The key is to use the right amount of ink; too much can lead to messy prints, while too little may result in incomplete coverage.

Follow the manufacturer’s guidelines for the recommended quantity based on your design size and complexity. Once the ink is applied, gently place your film onto the ink, ensuring complete contact between the two surfaces. Apply even pressure across the entire area to prevent air bubbles or uneven adhesion. Allow the ink to dry completely according to the product specifications before proceeding to the next step in your DTF printing process.

Heating and Curing the Print: Ensuring Quality and Durability

After applying your direct-to-film (DTF) print, the next crucial step is heating and curing it properly. This process ensures that the ink fully fuses with the substrate, enhancing both the print’s quality and durability. Start by preheating your printer or heat press to the recommended temperature, which varies depending on the type of ink and material used. Typically, this ranges between 120°C to 180°C (248°F to 356°F). Once heated, carefully place the printed substrate onto the heating element or press, ensuring even contact. The duration of curing depends on the thickness of your print and the specific ink characteristics; it usually ranges from a few minutes to as long as 15-20 minutes for thicker layers. Regularly check the print during this time to prevent overheating, which can cause ink bleeding or damaging the material.

Curing allows the ink to set and polymerize, resulting in a vibrant, long-lasting image. It’s essential to respect the recommended curing time to avoid inferior prints that may peel, fade, or lose their texture. After curing, carefully remove the print from the heating element or press, allowing it to cool down before handling. This step ensures your DTF print is not only visually appealing but also built to last, making it a preferred method for creating high-quality, long-lasting decorations on various materials.

Post-Print Care and Maintenance: Maximizing Your DTF Results

After printing with direct-to-film (DTF) technology, proper care and maintenance are crucial to ensure your prints last and maintain their high-quality appearance. Start by allowing the print to cool down before handling it; heat can cause warping or smudging. Then, gently clean the print using a soft cloth or brush to remove any dust or debris. Avoid using harsh chemicals or cleaning solutions as they can damage the print.

For long-term preservation, store your DTF prints in a cool, dry place, away from direct sunlight and moisture. Consider framing them for added protection, especially if they are valuable or meant for display. Regularly inspect your prints for any signs of wear and tear, such as scratches or fading, and address these issues promptly to maintain the integrity of your DTF results.